What is extrusion?

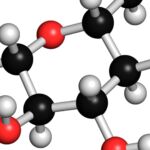

According to the market database, it is noted that extrusion is now a crucial step in the production of pet food. The production of homogeneous pet food is noted in the output associated with the incorporation of this technology. It essentially makes use of extrusion machines that utilize one or two screws to push the component mixture through the mould to create particular shapes and lengths. This in turn allows for the pet food to be transported, mixed, sheared, kneaded, shaped, or cooked. Thus transforming various ingredients into a homogeneous food product.

Market dynamics for pet food

Market research tools suggest that the overall pet food market is seen to undergo a substantial change owing to the changing consumer preferences. Business intelligence tools state that consumers are growing more specific about their requirements in terms of pet food ingredients. One of the primary factors driving this increased awareness amongst the population about the pet foods segment is the growing affinity of the masses toward animals. The number of people with pet dogs was seen to witness a massive growth between the years 2014-2022. Moreover, even during the pandemic while the global market was seen to witness heavy duress: Samaritans were known to take responsibility to feed animals to prevent mass starvation.

As per market research tools, factors like an increased focus on animal health and the growing propensity to adopt pets are hereby poised to be one of the key factors that boost market growth. Moreover, business intelligence tools state that in terms of pet food ingredients, it is noted that the population has placed demands in terms of ingredients, i.e. they wanted the food to be not just organic and natural but with high contents of meat as well. Pet foods with high meat content are one of the fast-growing market requirements. However, as per the market database, the extrusion process associated with this product comes with challenges of its own. The high meat content is usually over a value of 30%. To mimic the texture and appearance of meat, low-quality animal protein may occasionally be combined with trace amounts of vegetable protein. Quality attributes like digestibility are also noted to be one of the factors that govern the texture associated with pet food. Better-quality pet food is becoming more popular, as measured by its components, nutrition, and flavor. The production stages suggest that if dry animal components are employed, a single-screw, medium-shear extruder can produce high-meat, dry pet foods.

Challenges associated with the production of animal-based pet food as per the market database

The raw and wet ingredient-based extrusion process is noted to be more challenging. The process conditions state that to reach the proper cooking temperature, the moisture and fat in raw animal ingredients must balance out the friction in the extruder barrel. A mixture of various ingredients with different textures is noted to be a key challenge, consistent processing is required to yield high-quality products.

In terms of production processes, it is noted that due to the enhanced mixing and kneading capabilities inside the twin screw design, twin screw extruders have the processing advantage over single screws for the extrusion of high-meat pet food.

However, the production challenges associated with the manufacturing of high-quality kibble are noted to be a combination of various process variables, i.e. attaining the set safety standards while adhering to manufacturing practices that are of high efficiency. Cost versus production efficiency as well as the volume of production is a tricky trade-off study. Especially in the case of consumables owing to the stringent standards of regulations imposed across the global markets. Moreover, the shift towards sustainable practices has led to an increased intensification as well as optimization of process conditions for various manufacturing techniques. The wave of automation within the industrial segment is also noted to be one of the parameters which accelerate the quality of production and help maintain homogeneity across the products.

Extrusion dog food, also known as the processing of kibble is noted to witness various market demands in terms of shape/ size/ texture as well as nutrition. Shape retention and the ease of digestion associated with the product are some of the other variables that dictate the quality of the kibble. For instance, it is quite simple to extrude shaped kibbles from fresh meat, but it is more difficult to do so with a 75% inclusion rate, without grains, and with synthetic binders.